Strategic tips for Technology & Digital Transformation for manufacturing firms

Strategic Tips for Technology & Digital Transformation in Manufacturing Firms (A Tamil Nadu Perspective)

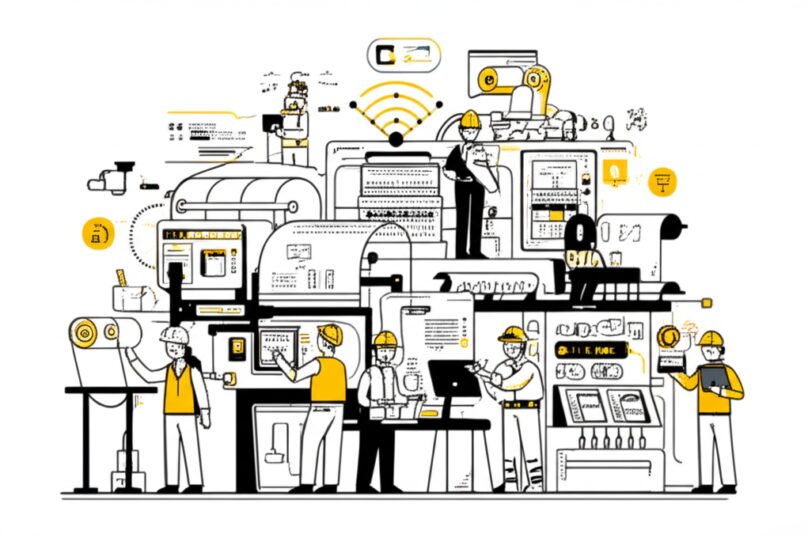

Hello, amazing founders, marketers, and business leaders! Today, let’s talk about something super important for every manufacturing business, especially here in our vibrant Tamil Nadu: Digital Transformation. Don’t let the big words scare you! It simply means using new technology to make your business run better, faster, and smarter. Think of it like giving your old, trusted cycle an electric motor and GPS – same cycle, but now it’s super-powered!

Why is this important now? Because the world is moving fast. If our manufacturing firms in Tamil Nadu want to stay ahead, grow, and create more jobs, embracing technology isn’t just an option; it’s a must. We’ve seen many local businesses make amazing strides, and we want to share some secrets with you.

Here are some simple, practical tips that we’ve seen work wonders for our clients right here in Tamil Nadu:

1. Understand Your Current Operations First

Before you jump into buying new software or machines, take a good look at how things are done now. Imagine you want to make a yummy filter coffee. First, you need to know how you currently make it – what ingredients you use, what steps you follow. It’s the same for your factory.

- Practical Tip: Write down every single step, from getting raw materials to sending out the finished product. See where things slow down or where mistakes happen.

- Tamil Nadu Example: A client of ours, Aravind Foundry in Coimbatore, which makes metal parts, spent a month just mapping out their old casting process. They found that a simple step in quality check was taking too long. Once they understood this, they could easily see where technology could help.

2. Make Friends with Data

Think of data as hidden treasure. Every machine, every sale, every customer interaction creates data. When you collect and understand this data, it tells you what’s working, what’s not, and where you can make more money. It’s like knowing the exact temperature for the perfect dosa batter!

- Practical Tip: Start collecting data from your machines (how much they produce, when they stop), your sales (what sells most), and your customers (what they like). Use simple tools like spreadsheets if needed, to begin with.

- Tamil Nadu Example: Chennai Auto Components Ltd. in Chennai used data from their car part assembly line. They noticed that a specific machine was having small delays every few hours. By fixing this based on the data, they reduced waste by 15% and produced more parts in the same time!

3. Embrace Smart Machines (Automation & IoT)

This sounds fancy, but it’s really about letting machines do the repetitive or dangerous jobs so your skilled workers can do more important tasks. IoT (Internet of Things) means connecting machines so they can talk to each other and to you. Think of a smart light bulb you can control with your phone.

- Practical Tip: Look for tasks that are done over and over, or are risky for humans. Can a robot arm do it? Can a sensor tell you when a machine needs oil?

- Tamil Nadu Example: Sri Lakshmi Textiles in Coimbatore installed small sensors (IoT) on their weaving machines. These sensors would warn them *before* a machine broke down. This helped them fix issues quickly, saving them hours of repair time and huge costs from stopping production.

4. Connect Your Supply Chain Digitally

Your supply chain is like the railway track that brings all the raw materials to your factory and takes the finished goods to your customers. If you can see everything happening on this track in real-time, you can avoid delays and keep everyone happy.

- Practical Tip: Use simple software or even shared online documents to track your raw materials from where they come from, to when they reach you, and where your finished goods are going.

- Tamil Nadu Example: Velan Agro Foods in Madurai, which makes mango pulp, used a simple app to track mangoes from local farms to their factory. They knew exactly which farm the mangoes came from and when they would arrive. This ensured only the freshest mangoes were used, making their product taste even better!

5. Invest in Your People’s Skills

Technology is great, but your people are even greater! They need to know how to use these new tools. It’s like buying a new, advanced cooking stove – you need to teach your chef how to use it for the best results.

- Practical Tip: Provide easy-to-understand training for your employees on any new software or machine. Make it fun and show them how it helps them do their job better.

- Tamil Nadu Example: Kumaran Garments in Tirupur, a famous garment exporter, trained their workers on new digital design software and automated cutting machines. At first, it was challenging, but soon, their workers became super-efficient, creating new designs faster and with less waste.

6. Keep Your Digital House Safe (Cybersecurity)

When you go digital, you also need to protect your digital information from bad guys. Think of it like putting strong locks on your factory doors. Cybersecurity means protecting your valuable data from hackers.

- Practical Tip: Use strong, unique passwords. Be careful about opening strange emails. Have a simple plan for what to do if something goes wrong.

- Tamil Nadu Example: A small plastics manufacturer, Priya Plastics in Kancheepuram, learned this the hard way when their production schedule was almost lost due to a computer virus. They quickly set up stronger firewalls and trained their staff, ensuring their business data was safe and sound.

Conclusion: Start Small, Think Big!

Digital Transformation doesn’t mean you have to change everything overnight. You can start with one small step. Pick one area, try a new technology, learn from it, and then expand. The goal is to make your manufacturing business stronger, more competitive, and ready for the future.

By embracing these simple tips, our manufacturing firms in Tamil Nadu can continue to be leaders, create more opportunities, and build a brighter future for everyone. Let’s build better brands, together!