Leveraging Manufacturing & Industry 4.0

Leveraging Manufacturing & Industry 4.0 in Tamil Nadu: A Practical Guide for Growth

Tamil Nadu, a hub of manufacturing in India, is experiencing a significant transformation with the adoption of Industry 4.0 technologies. This guide explores how businesses in the state can leverage these advancements for enhanced productivity, efficiency, and competitiveness.

Understanding Industry 4.0

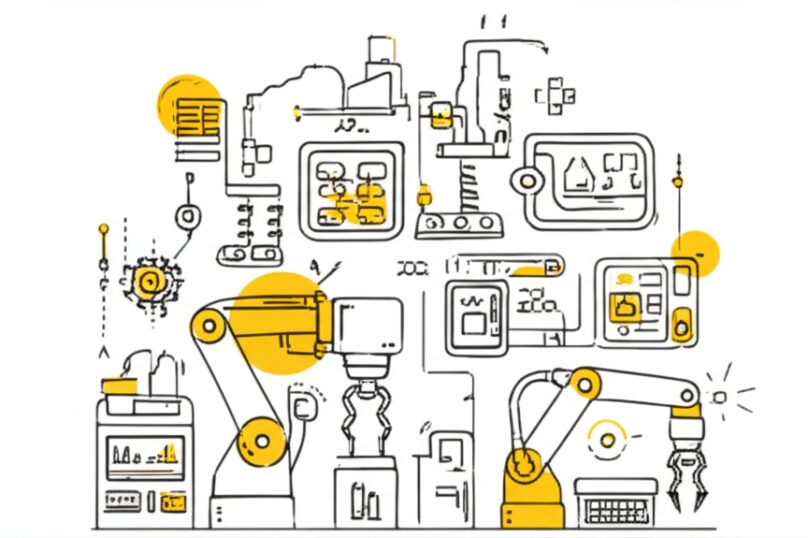

Industry 4.0, also known as the fourth industrial revolution, involves the integration of cyber-physical systems, the Internet of Things (IoT), cloud computing, and artificial intelligence (AI) into manufacturing processes. Think of it like giving your factory a super-smart brain! This allows for automation, data-driven decision-making, and improved overall performance.

Practical Applications in Tamil Nadu

Many Tamil Nadu companies are already reaping the benefits of Industry 4.0. Consider these examples:

- Smart Factories: Companies like XYZ Manufacturing in Coimbatore have implemented smart factory solutions, using sensors and data analytics to optimize their production lines. This has led to a significant reduction in waste and improved product quality.

- Predictive Maintenance: ABC Auto Parts in Chennai uses IoT sensors to monitor the health of their machinery. This allows them to predict potential equipment failures and schedule maintenance proactively, minimizing downtime and reducing repair costs. Imagine knowing your machine needs a checkup *before* it breaks down!

- Supply Chain Optimization: PQR Textiles in Tiruppur uses blockchain technology to track their supply chain, ensuring transparency and efficiency in their operations. This increases traceability and reduces the chances of disruptions.

- Robotics and Automation: Several companies in the automotive and electronics sectors in Tamil Nadu have implemented robotics for tasks such as welding, painting, and assembly. This improves speed, accuracy, and consistency.

Benefits for Tamil Nadu Businesses

Embracing Industry 4.0 offers numerous benefits:

- Increased Productivity: Automation and optimized processes lead to higher output with the same or fewer resources.

- Reduced Costs: Predictive maintenance, waste reduction, and efficient supply chains save money.

- Improved Quality: Automation and data-driven insights ensure consistent product quality.

- Enhanced Competitiveness: Industry 4.0 helps companies stay ahead in the global market.

- Better Data-Driven Decision Making: Real-time data provides insights for better strategic planning.

Getting Started

Implementing Industry 4.0 might seem daunting, but it’s a journey, not a sprint. Start small, focus on areas with the highest impact, and gradually expand your adoption. Consider:

- Assessment: Identify areas for improvement in your current processes.

- Pilot Projects: Start with a small-scale project to test the technology and its benefits.

- Training: Equip your workforce with the skills to operate and maintain new technologies.

- Partnerships: Collaborate with technology providers and consultants for support.

Conclusion

Industry 4.0 presents a tremendous opportunity for businesses in Tamil Nadu to enhance their operations and compete effectively. By embracing these advancements, companies can unlock significant growth and secure their place in the future of manufacturing.