Lean Manufacturing: A Case Study of Efficiency Gains in an Automotive Plant

Lean Manufacturing: Making Things Super Smart and Smooth – A Real Story from Tamil Nadu

Hello, amazing business owners, sharp marketers, and clever leaders!

Imagine you have a big kitchen. Sometimes, you might have too many ingredients lying around, or you spend too much time finding the right spoon. This makes cooking slow and sometimes even spoils the food. What if there was a way to make your kitchen super organised, so you cook faster, better, and with less waste?

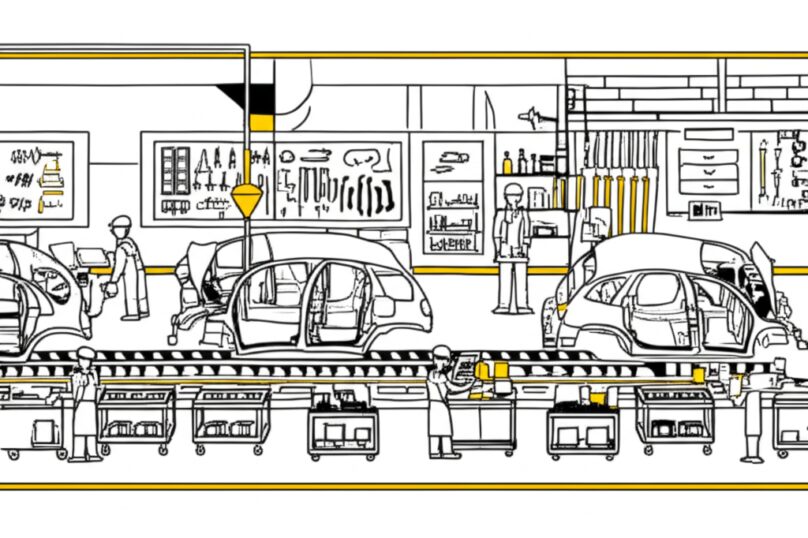

That “way” is called Lean Manufacturing. It’s a smart way of working that helps businesses do more with less, remove waste, and make things super smooth. Even if you don’t make things in a factory, the ideas behind Lean can help your business be much better, whether you’re selling, marketing, or leading people.

Today, we’re going to look at a real-life example from our very own Tamil Nadu to see how a simple idea can make a huge difference.

The Big Problem at “Sri Lakshmi Auto Parts”

Let’s talk about a company called “Sri Lakshmi Auto Parts” located near Coimbatore. They make important parts for cars and bikes. For a long time, they faced some big problems:

- They had too many parts piled up everywhere, like a big mountain of things. This meant money was stuck, and it was hard to find what was needed.

- Workers often had to wait for materials or for the next machine to be free. This was like waiting in a long queue, wasting precious time.

- Sometimes, they made too many parts, more than what customers needed right then. This led to wasted materials and storage space.

- It took a very long time for a part to go from the start of the factory to the end.

These problems made their costs go up, and sometimes, customers had to wait longer for their orders. Sri Lakshmi Auto Parts knew they needed a change.

How Lean Manufacturing Came to the Rescue

The team at Sri Lakshmi Auto Parts decided to try Lean Manufacturing. It’s not just about machines; it’s about changing how people think and work. Here’s what they did, step-by-step:

1. Finding the “Waste” (Muda)

First, they learned to see what was “waste.” In Lean, “waste” is anything that doesn’t add value for the customer. Think of it like this:

- Waiting around: Workers waiting for parts or machines.

- Too much stuff: Having extra parts or products that aren’t needed right away.

- Too much movement: People walking too far to get tools or materials.

- Making mistakes: Having to fix errors later.

- Extra processing: Doing more work than what’s truly needed.

They walked through their factory and marked down every single waste they saw. It was like going on a treasure hunt to find hidden problems!

2. Making Things Flow Smoothly (Value Stream Mapping)

Next, they drew a big map of how their parts were made, from start to finish. This map showed every step and how long it took. They saw where the parts got stuck or where things slowed down. Their goal was to make the flow like a river, smooth and continuous, without any dams or blocks.

3. The “5S” Magic for a Tidy Workplace

Sri Lakshmi Auto Parts then used something called 5S. It’s a simple way to keep the workplace neat and organised. Imagine cleaning up your room so everything has a place and is easy to find:

- Sort (Seiri): Remove everything that isn’t needed. (Like removing old toys you don’t play with).

- Set in Order (Seiton): Arrange things so they are easy to find and use. (Like putting all your pens in one cup).

- Shine (Seiso): Clean the workplace regularly. (Like cleaning your desk every day).

- Standardise (Seiketsu): Make rules to keep things organised and clean. (Like having a rule that everyone puts their books back).

- Sustain (Shitsuke): Keep doing it! Make it a habit. (Like making sure you always follow the rules).

Their factory floor became super clean and organised, making it easier and faster for workers to do their jobs.

4. Small Steps for Big Changes (Kaizen)

They started encouraging every worker, from the top boss to the person on the floor, to find small ways to make things better every single day. This is called Kaizen, a Japanese word for “continuous improvement.” For example, a worker suggested moving a tool shelf closer to a machine, saving many steps each day. These small changes added up to huge improvements.

5. Just-In-Time (JIT) – Having Exactly What You Need, When You Need It

Instead of piling up parts, Sri Lakshmi Auto Parts started getting materials and making parts only when they were needed for the next step. This is like getting ingredients for dinner just before you start cooking, not buying a huge stock for the whole year. This reduced their storage costs and stopped waste from unused parts.

The Amazing Results at Sri Lakshmi Auto Parts!

After a few months of putting these Lean ideas into practice, Sri Lakshmi Auto Parts saw amazing changes:

- Faster Production: The time it took to make a car part from start to finish was cut down by 30%! This meant they could make more parts in the same amount of time.

- Less Waste: They reduced wasted materials by a huge 25%, saving a lot of money.

- Lower Costs: Overall, their production costs went down because of less waste and more efficient working.

- Better Quality: Because processes were smoother and mistakes were caught faster, the quality of their parts improved significantly.

- Happier Workers: Workers felt more involved and proud of their clean, efficient workplace.

Sri Lakshmi Auto Parts became a shining example in Tamil Nadu of how smart working can transform a business!

How Can YOU Use Lean in Your Business? (Even if You Don’t Make Car Parts!)

You might be thinking, “But I don’t run a factory!” That’s okay! The ideas of Lean Manufacturing are powerful for ANY business, whether you’re a marketing agency, a consulting firm, a sales team, or a B2B/B2C business owner. Here’s how:

- For Marketers:

- Find Waste: Are there too many steps to approve a marketing campaign? Are you creating content that no one reads? Stop doing what doesn’t bring value.

- Smooth Flow: Make your content creation or ad campaign launch process super smooth, from idea to going live.

- Continuous Improvement: After every campaign, ask: “What worked well? What can we do better next time?”

- For Salespeople:

- Eliminate Waste: Are you spending too much time on leads that will never buy? Can you make your sales calls shorter but more effective?

- Just-In-Time: Send proposals or follow-ups exactly when the customer is ready, not too early or too late.

- Standardise: Have a clear, efficient way to handle customer queries or objections.

- For Consultants and Business Owners:

- Optimise Your Services: Can you deliver your consulting advice or products faster and with higher quality?

- Improve Internal Processes: Look at how you manage your team, your finances, or your customer service. Where can you remove waiting or extra steps?

- Focus on Customer Value: What truly matters to your clients? Focus all your energy on delivering that, and remove anything else.

The Big Idea: Do More, Better, with Less!

Lean Manufacturing is not just a fancy term; it’s a mindset. It teaches us to constantly look for ways to make things better, remove waste, and deliver more value. Just like Sri Lakshmi Auto Parts transformed their factory in Tamil Nadu, you can transform your business. Start small, look for waste, and always aim for continuous improvement.

What “waste” will you remove from your business today?