Key trends in Operations Management for manufacturing firms

Welcome, Business Leaders!

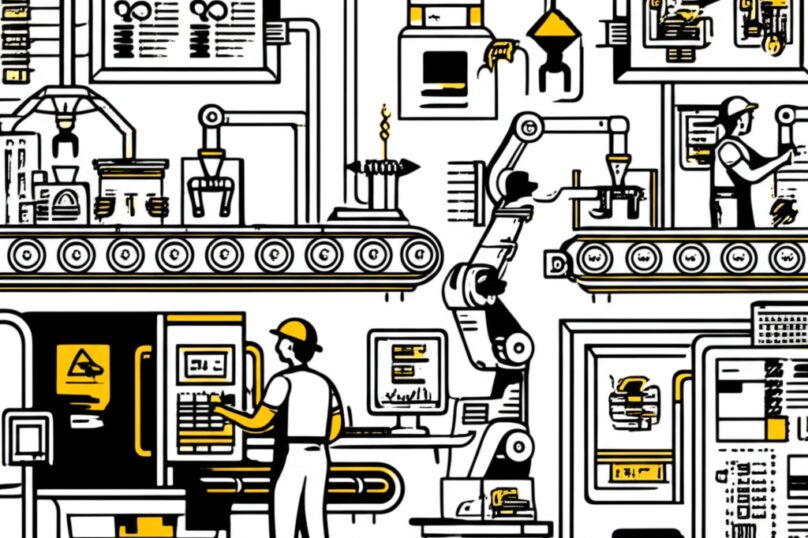

In today’s fast-paced world, managing a manufacturing firm successfully is like directing a symphony. Every part must work together perfectly. This is where Operations Management comes in – it’s all about making sure your factory runs smoothly, produces quality goods, and delivers them on time. For our wonderful businesses right here in Tamil Nadu, staying updated with the latest trends in Operations Management isn’t just good advice, it’s a must for growth.

We’ve seen these trends transform many of our clients’ businesses. Let’s dive into what’s making a big difference!

1. The Rise of Smart Factories (Industry 4.0)

Imagine a factory where machines talk to each other, tell you when they need fixing, and even adjust their own settings for better production. This is the idea behind Smart Factories, powered by something called Industry 4.0. It uses technology like the Internet of Things (IoT) and big data to make manufacturing smarter and more efficient.

- What it means: Using sensors, data, and interconnected machines to make real-time decisions.

- Why it helps: Less downtime, better quality, and faster production.

Real-world example from Tamil Nadu: Remember “Kumar Textiles” in Coimbatore? They used to face issues with their weaving machines breaking down often. We helped them install small sensors on each machine. These sensors now tell them exactly when a machine needs maintenance before it breaks down. This saved them lakhs of rupees in lost production and repair costs, ensuring their famous silk sarees were always ready on time.

2. Lean Manufacturing & Waste Reduction

Think of Lean Manufacturing as getting rid of anything that doesn’t add value to your product. It’s about being super efficient and reducing all kinds of waste – from wasted materials to wasted time.

- What it means: Doing more with less, focusing on value for the customer.

- Why it helps: Lower costs, faster delivery, and higher customer satisfaction.

Real-world example from Tamil Nadu: “Ganesh Plastics” in Trichy, a small firm making plastic parts, struggled with too much scrap material. We worked with them to identify where the waste was happening in their process. By simply rearranging their production line and training staff to be more careful, they cut down their scrap by 20% in just three months. This small change made a big impact on their profits.

3. Optimizing Your Supply Chain

Your supply chain is like the road network for your business – it’s how raw materials come in and finished products go out. Making this network smooth and strong is crucial. Today, firms are focusing on making their supply chains flexible and quick to respond to changes.

- What it means: Better planning, strong relationships with suppliers, and smart logistics.

- Why it helps: Faster delivery, less stock wastage, and happier customers.

Real-world example from Tamil Nadu: “Sakthi Ceramics” in Sivakasi faced challenges getting their tiles to dealers across Tamil Nadu quickly, especially during festive seasons. We helped them set up a better system to track their inventory and coordinate with transporters. They even started using a digital platform to communicate with their raw material suppliers. Now, their tiles reach stores faster, and they rarely face stock shortages, leading to increased sales.

4. Automation and Robotics

Robots aren’t just for sci-fi movies anymore! Many factories in Tamil Nadu are using automation and robotics to do repetitive or dangerous tasks. This frees up human workers to focus on more creative and skilled jobs.

- What it means: Using machines and robots for tasks like welding, assembling, or packaging.

- Why it helps: Increased speed, consistent quality, and improved safety for workers.

Real-world example from Tamil Nadu: A leading auto component manufacturer near Chennai, let’s call them “Velayudham Auto Parts,” invested in robotic arms for their welding section. Before, welding was slow and sometimes dangerous for workers. With robots, they achieved perfect welds every time, much faster, and workers could be assigned to quality control and robot supervision, making the workplace safer and more efficient.

5. Data Analytics and Artificial Intelligence (AI)

Every factory produces a lot of data – from how many items are made to how much energy is used. Data analytics is like having a superpower to understand all this information, and AI helps you make smart predictions based on it.

- What it means: Using software to understand patterns in data and AI to predict future outcomes.

- Why it helps: Better planning, spotting problems early, and making smarter business decisions.

Real-world example from Tamil Nadu: “Kaveri Foundry” in Salem, known for its precision castings, used to struggle with unexpected machine breakdowns. We helped them implement a system that collects data from their machines – like temperature, vibration, and power usage. Using simple AI tools, they can now predict when a machine is likely to fail, allowing them to do maintenance beforehand and avoid costly production stops. This proactive approach has significantly boosted their uptime.

Wrapping It Up!

The world of manufacturing is always changing, and these trends in Operations Management are not just buzzwords; they are practical tools that can genuinely help your business thrive. By adopting smart factories, practicing lean methods, optimizing your supply chain, embracing automation, and leveraging data, your firm can not only survive but truly excel.

We at LetUs Business Consulting are passionate about helping Tamil Nadu businesses embrace these changes. If you’re looking to transform your operations and build a stronger, more efficient future, reach out to us!

Stay smart, stay strong!