Boosting Manufacturing & Industry 4.0 in small businesses

Hello amazing business owners and leaders!

Today, we’re diving into something super important for every small business in Tamil Nadu: Boosting Manufacturing & Industry 4.0. Don’t let the fancy words scare you! Think of it as making your factory smarter, faster, and much more profitable, just like we helped many businesses right here in our own backyard.

What Exactly is Industry 4.0? Simple Explanation!

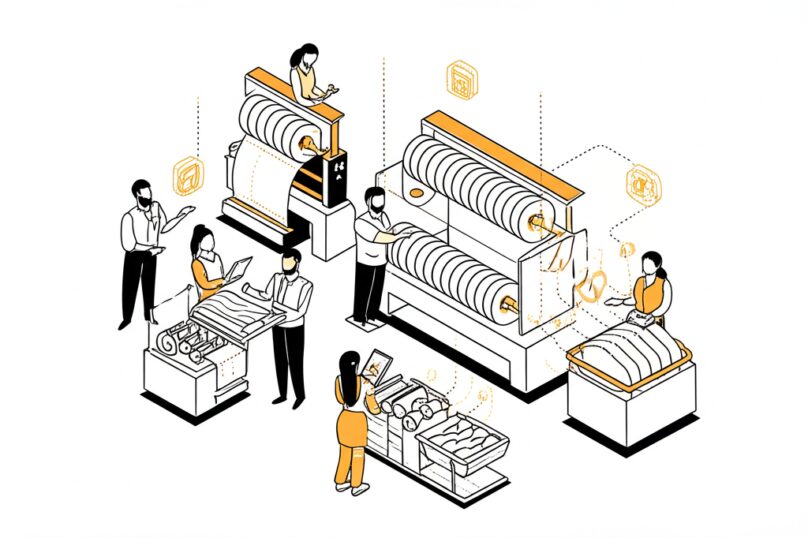

Imagine your factory machines talking to each other. Imagine them telling you exactly when they need fixing or how much they have produced. That’s Industry 4.0! It’s about using computers, sensors, and smart tools to make your manufacturing process very efficient. It’s like giving your old factory a super-smart brain!

Why Small Businesses in Tamil Nadu Need This Super-Smart Brain?

You might think, “This is only for big companies, right?” Wrong! Industry 4.0 is even more helpful for small and medium businesses (SMBs) in places like Chennai, Coimbatore, and Madurai. Here’s why:

- Save Money (Costs): Smart machines waste less material and energy. This means more money in your pocket.

- Make Things Faster: When machines work together smartly, your products get made quicker. This means you can deliver faster to your customers.

- Better Quality Products: With smart checks, fewer mistakes happen. Your products will be of top-notch quality, making customers happier.

- Compete with Bigger Companies: This technology helps you do things as efficiently as big players, giving you a strong edge in the market.

- Be Ready for the Future: The world is changing fast. Embracing this technology keeps your business strong and ready for anything.

How Can Small Businesses Start with Industry 4.0? Simple Steps We Followed!

You don’t need to change everything overnight. Here’s a simple, step-by-step guide based on what we’ve successfully implemented for our clients:

-

Step 1: Understand Your Factory First:

Before buying new tech, look at your existing factory. What machines do you have? Where do you face problems? Is it too much waste, slow production, or machine breakdowns? For example, a small textile unit in Tirupur, “Kumaran Cottons,” first noted their main issue was fabric waste during cutting.

-

Step 2: Start Small (Pilot Projects):

Don’t try to automate everything at once. Pick one small area where you have a big problem. We helped “Azhagan Plastic Works” in Erode, a small plastic recycling unit, by just adding smart sensors to their shredding machines to monitor temperature and prevent overheating. This one small change saved them a lot of repair costs.

-

Step 3: Collect Data – Your Factory’s Secret Language:

Your machines produce data. This data is like your factory’s voice. Smart sensors can help you listen to it. For instance, “Muthu Sweets” in Villupuram, a traditional snack maker, installed simple sensors to track the exact temperature and mixing time of their dough. This helped them keep taste consistent every single time.

-

Step 4: Use Data to Make Smart Decisions:

Once you have the data, use it! If a machine often breaks down on Tuesdays, the data will show it. Then you can fix it before it breaks. We guided “Saravanan Motors,” a small auto parts manufacturer in Coimbatore, to use data from their welding machines. They could predict when a machine needed servicing, which reduced their downtime by 20% and helped them deliver orders on time.

-

Step 5: Train Your Team – They Are Your Superheroes!:

Industry 4.0 is not about replacing people; it’s about helping them work smarter and safer. Train your workers on how to use these new tools. When we introduced new digital systems at “Gomathi Foods” in Salem, a small rice mill, we spent time explaining how it makes their job easier, not harder. They became champions of the new system!

Real-Life Tamil Nadu Success Stories (Our Clients):

Here are some examples of how local businesses like yours made a big difference with Industry 4.0:

-

Case Study 1: “Velan Garments” in Tirupur (Textile Industry)

Challenge: High fabric waste and inconsistent stitching quality.

Solution: We helped them install smart sensors on cutting machines and quality check points. These sensors monitored fabric alignment and stitch consistency in real-time.

Result: They reduced fabric waste by 15% and significantly improved their garment quality, leading to happier buyers and fewer returns. Their brand name grew stronger!

-

Case Study 2: “Sakthi Engineering” in Coimbatore (Auto Parts Manufacturing)

Challenge: Frequent machine breakdowns caused delays in delivery and high repair costs.

Solution: We implemented a predictive maintenance system. Sensors on their heavy machinery would detect early signs of wear and tear, alerting them before a breakdown happened.

Result: Machine downtime was reduced by an impressive 20%. This meant consistent production, on-time deliveries, and saving lakhs of rupees on emergency repairs.

-

Case Study 3: “Anna Spices” in Virudhunagar (Food Processing)

Challenge: Manual sorting and packaging led to slower production and occasional errors in spice mixtures.

Solution: We introduced automated sorting machines with vision systems (smart cameras) and integrated packaging lines.

Result: They increased their daily output by 10% and ensured perfect spice blend consistency, enhancing their brand’s reputation for quality. Their market reach expanded!

The Big Benefits for Your Business:

By bringing Industry 4.0 to your small business, you are not just adopting technology; you are building a stronger, more resilient future:

- More Profits: By cutting waste and making things faster.

- Less Stress: By predicting problems before they happen.

- Happier Customers: By delivering high-quality products on time.

- Future-Ready Business: By staying ahead of the competition.

Don’t wait for tomorrow to make your business smarter. The journey to Industry 4.0 begins with a single step. We’re here to help you take that step, just like we’ve done for many successful businesses across Tamil Nadu!