10 Ways to improve Manufacturing & Industry 4.0

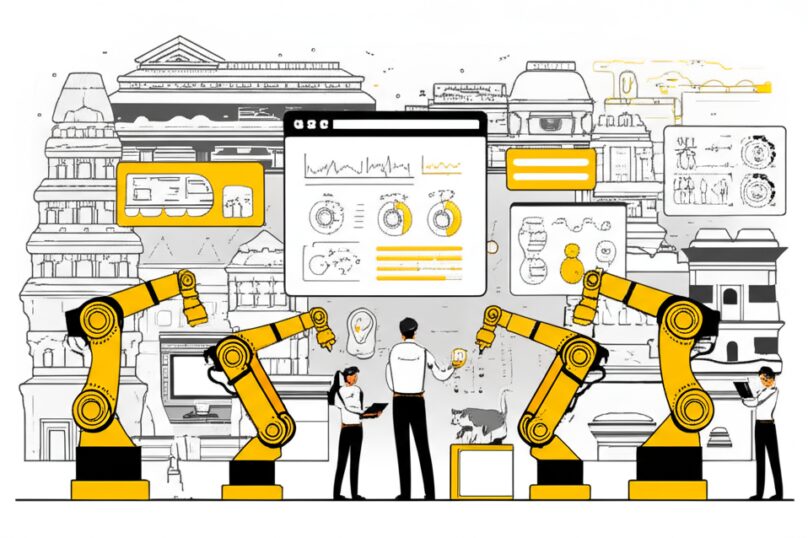

Hello, amazing business leaders and innovators! Today, we’re diving into something super important for every business in Tamil Nadu: Manufacturing & Industry 4.0. Think of Industry 4.0 as the “smart” way factories and businesses work now, using computers and new technologies to make things better, faster, and more efficiently. It’s all about bringing the future into our factories today!

We know you’re always looking for ways to grow your brand and make your operations top-notch. So, here are 10 practical ways to embrace Industry 4.0, with real-world examples from our very own Tamil Nadu, just like we’ve helped our clients do.

1. Smart Factories with IoT (Internet of Things)

Imagine your machines talking to each other and telling you exactly what they need! That’s IoT. It uses small sensors to collect data, helping you understand how everything is working.

- What it is: Connecting machines, sensors, and devices to the internet so they can share information.

- Why it helps: You can see problems before they happen, making production smoother.

- Tamil Nadu Example: A famous textile factory in Coimbatore, “Kumar Textiles,” installed tiny sensors on their weaving machines. These sensors told them when a machine was getting too hot or needed oil, preventing sudden breakdowns and saving lots of money and time.

2. Automation & Robotics

Robots aren’t just for movies anymore! They can do repetitive and sometimes dangerous tasks, letting people focus on more important, creative work.

- What it is: Using machines and robots to do tasks automatically.

- Why it helps: Faster production, fewer mistakes, and safer workplaces.

- Tamil Nadu Example: “Chennai Auto Parts Pvt Ltd” in Chennai uses robots for welding car parts. These robots work tirelessly, making sure every weld is perfect and speeding up their production line significantly.

3. Big Data Analytics

Your business generates tons of data every day. Big Data Analytics is like having a superpower to understand all that information and make smart choices.

- What it is: Collecting and understanding huge amounts of data to find patterns and make predictions.

- Why it helps: Better decisions about what to produce, when, and for whom.

- Tamil Nadu Example: “Madurai Modern Foods,” a snack company in Madurai, started analyzing their sales data. They found that their spicy murukkus sold much more on weekends. This helped them plan production better and reduce waste.

4. Cloud Computing

Think of cloud computing as a super-safe, online storage locker for all your important business information, accessible from anywhere.

- What it is: Storing data and running applications over the internet instead of on your own computers.

- Why it helps: Easy access to information for your team, lower costs for IT, and great security.

- Tamil Nadu Example: “Trichy Engineering Solutions,” a small but growing engineering firm in Trichy, uses cloud software to manage all their project designs. Their engineers can work on projects from different cities, collaborating smoothly and efficiently.

5. Cybersecurity

As we use more digital tools, protecting our information from online threats becomes super important. Cybersecurity is like a strong fort for your data.

- What it is: Protecting computer systems and networks from digital attacks and theft.

- Why it helps: Keeps your valuable business secrets safe and builds trust with your customers.

- Tamil Nadu Example: A leading pharmaceutical company near Pondicherry (which serves many clients in Tamil Nadu), “Pondy Pharma Ltd,” invested heavily in cybersecurity to protect their new medicine formulas and patient data from hackers, ensuring their reputation remained strong.

6. Additive Manufacturing (3D Printing)

Imagine printing a solid object, layer by layer, directly from a computer design. That’s 3D printing!

- What it is: Creating three-dimensional objects by adding material layer by layer (e.g., 3D printing).

- Why it helps: Quick creation of prototypes, complex designs, and custom products.

- Tamil Nadu Example: “Chennai Gems & Jewels,” a local jewelry maker in Chennai, uses 3D printing to create intricate molds for their gold and diamond jewelry. This allows them to make unique designs faster and with less waste.

7. Augmented Reality (AR)

AR mixes the real world with computer-generated images, like seeing digital instructions appear on a real machine while you’re working on it.

- What it is: Overlaying digital information onto the real world, often using special glasses or tablets.

- Why it helps: Easier training, better maintenance guides, and improved quality control.

- Tamil Nadu Example: An electronics assembly plant in Hosur, “Hosur Tech Assembly,” started using AR glasses for training new workers. The glasses showed step-by-step instructions directly onto the components, making learning super fast and reducing errors.

8. Digital Twins

A digital twin is a virtual copy of a real machine, building, or even a whole factory. You can test changes on the digital copy without touching the real one!

- What it is: Creating a virtual model of a physical object or system.

- Why it helps: Test new ideas, predict problems, and improve performance without risk.

- Tamil Nadu Example: “Kanyakumari Wind Power,” a wind turbine manufacturer in Kanyakumari, created digital twins of their huge wind turbines. They could see how different weather conditions would affect their turbines and even predict when a part might need replacing, all from their office.

9. Supply Chain Optimization

This is about making sure products move smoothly from where they are made to where they are sold, without delays or waste.

- What it is: Using technology to make the movement of goods and information from supplier to customer more efficient.

- Why it helps: Faster delivery, lower costs, and happier customers.

- Tamil Nadu Example: “Erode Fresh Foods,” a large supplier of vegetables in Erode, used tracking technology to monitor their truck fleet. They could see exactly where each truck was, ensuring fresh vegetables reached markets in Coimbatore and Madurai on time, every time.

10. Predictive Maintenance

Instead of fixing a machine after it breaks, predictive maintenance uses data to fix it just before it breaks!

- What it is: Using data and sensors to predict when equipment needs maintenance, preventing unexpected breakdowns.

- Why it helps: Reduces costly downtime, extends machine life, and improves safety.

- Tamil Nadu Example: A huge cement factory in Ariyalur, “Ariyalur Cement Works,” installed sensors on their grinding machines. These sensors would warn them days in advance if a part was wearing out, allowing them to schedule repairs without stopping the entire production line.

Embracing Industry 4.0 isn’t just about fancy new technology; it’s about making your business smarter, stronger, and ready for the future. By adopting these methods, inspired by our own successful implementations with clients across Tamil Nadu, you can build a truly powerful and resilient brand. It’s time to innovate and lead the way!